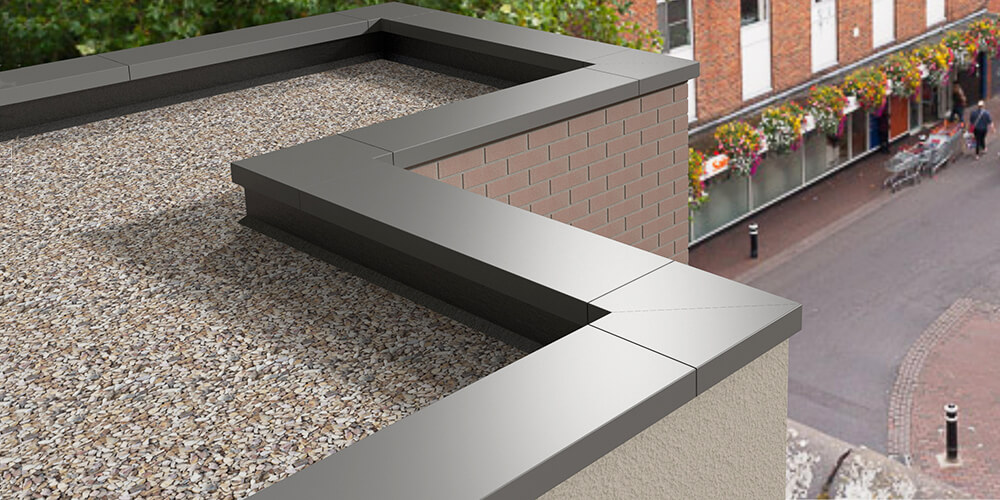

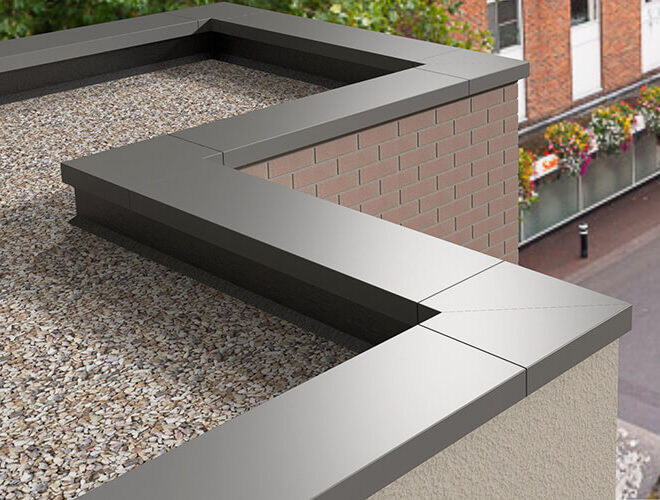

Aluminium Copings for Masonry – Timeless Protection, Modern Performance

Masonry construction demands coping solutions that respect traditional building methods while delivering contemporary performance. Our specialised aluminium copings are engineered specifically for brick, stone and blockwork applications, providing a perfect marriage of heritage aesthetics and modern material science. Unlike generic coping systems, every detail has been developed with masonry’s unique characteristics in mind.

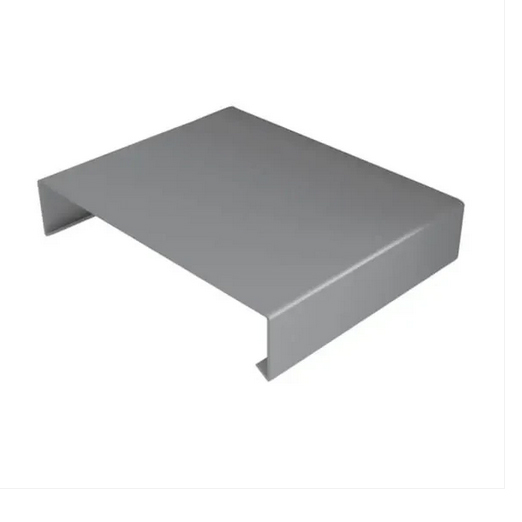

The foundation of our masonry-specific design lies in the precision-engineered base profile. We’ve incorporated a deeper cavity (minimum 50mm) to accommodate the natural variations in masonry surfaces, paired with an adjustable cleat system that compensates for irregular wall tops. This prevents the common issue of “rocking” that plagues standard copings on uneven masonry. The heavy-duty aluminium construction (2.5mm minimum thickness) stands up to the thermal movement stresses inherent in large masonry structures.

For heritage projects, we offer a range of traditional profiles that replicate historic lead or stone detailing in maintenance-free aluminium. Our craftsmen can recreate period-specific designs like ogee, chamfered or roll-top profiles, complete with authentic-looking patinated finishes. Modern buildings benefit from our concealed fixing systems that maintain clean lines while providing the robust protection masonry requires against driving rain and frost damage.

Installation is simplified through our masonry-specific accessories. The system includes corrosion-resistant stainless steel brackets spaced at 450mm centres, pre-formed internal corner units, and specially formulated sealants that remain flexible against porous substrates. We provide comprehensive installation drawings showing recommended mortar details and expansion joint placement for different masonry types.

The performance benefits for masonry structures are significant. Independent testing shows our copings reduce water absorption through wall tops by 92% compared to unprotected masonry, dramatically extending the lifespan of the structure below. The aluminium’s thermal conductivity helps prevent the freeze-thaw damage that plagues stone and brick in exposed locations.

Whether working with rugged Yorkshire stone, precision brickwork or textured blockwork, our technical team can advise on the optimal coping solution. We keep profiles for common heritage bricks (including imperial sizes) in stock, and can manufacture custom solutions for unusual masonry dimensions within 10 working days.

Aluminium Copings for Masonry – Get in Touch with us today!